Daewon Research Group

Nano Energy Device Laboratory

Research Highlight

> Research > Research Highlight

> Research > Research Highlight

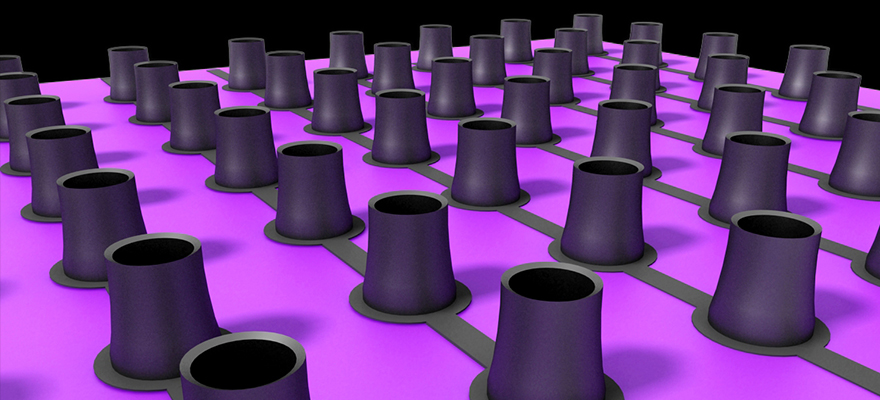

CarbonMEMS

C-MEMS (Carbon Microelectromechanical systems)

As all of the users’ demand to improve the response time of the electrical devices and to make it smaller, higher technology are required to be improved more than now. In regard of these demands, the components’ size is getting smaller and more components’ are required to be placed in the same area compared to the past. In these days, achievement of scale acquired for range from 20 micrometers to a millimeter.

To fabricate nano-scale devices, we should realize that the electrical force between atoms is much more needed to be concerned compared to a mechanical fabrication due to a scale law.

To solve out for a pre-mentioned problem, we don’t take a technology using a machine anymore. Instead, we adopted a new technology which is suitable. Deposition is the first step of it. We use sputtering and evaporation deposition.

Each, use a ion-beam to transfer a momentum by beam on the target to take off atoms to make it move in no restriction and evaporate the chemical gas to react with basic substance. And then we apply patterning technology to sketch up a melted part for a ready to make the figure what we want.

By the way, as generally announced, wafer is made by silicon. Which is rather unreactive and has a rich vein. But for the reason of the limitation for the sculpting of the carbon we are still using a silicon in the industry field even though the carbon has more strong points compared to a silicon.

Now in our laboratory, we are studying to fabricate with carbon and pretty nice property is coming out now.

Related Journals

Reduced Graphene Oxide/ZnO Nanorods Nanocomposite: Structural, Electrical and Electrochemical Properties [Link]

- Author : Swati Chaudhary, Leo Sam James, Althurthi Bharani Venkata Kiran*, Challa Veera Venkata Ramana, Dilip Kumar Mishra, Sabu Thomas, and Daewon Kim*

- Journal : Journal of Inorganic and Organometallic Polymers and Materials

- Published Date : 2019-11

- Volume / Issue / Page : 29 / - / 2282-2290

Enhancing humidity sensing performance of polyaniline/water soluble graphene oxide composite [Link]

- Author : Basavalingappa Chethan, Hotte Gowdru Raj Prakash, Yaled Thippeswamy Ravikiran*, Sanikere Channappa Vijayakumari, Challa Veera Venkata Ramana, Sabu Thomas, and Daewon Kim*

- Journal : Talanta

- Published Date : 2019-05

- Volume / Issue / Page : 196 / - / 337-344